Revolutionizing Automotive Transmissions: The Role of Hydraulic Clutch Release Bearings

Automotive transmissions have undergone significant advancements over the years to improve performance, efficiency, and overall driving experience. One crucial component that plays a role in revolutionizing transmissions is the hydraulic clutch release bearing (HCRB), also known as the concentric slave cylinder or hydraulic release system.

Traditional Manual Transmission Systems:

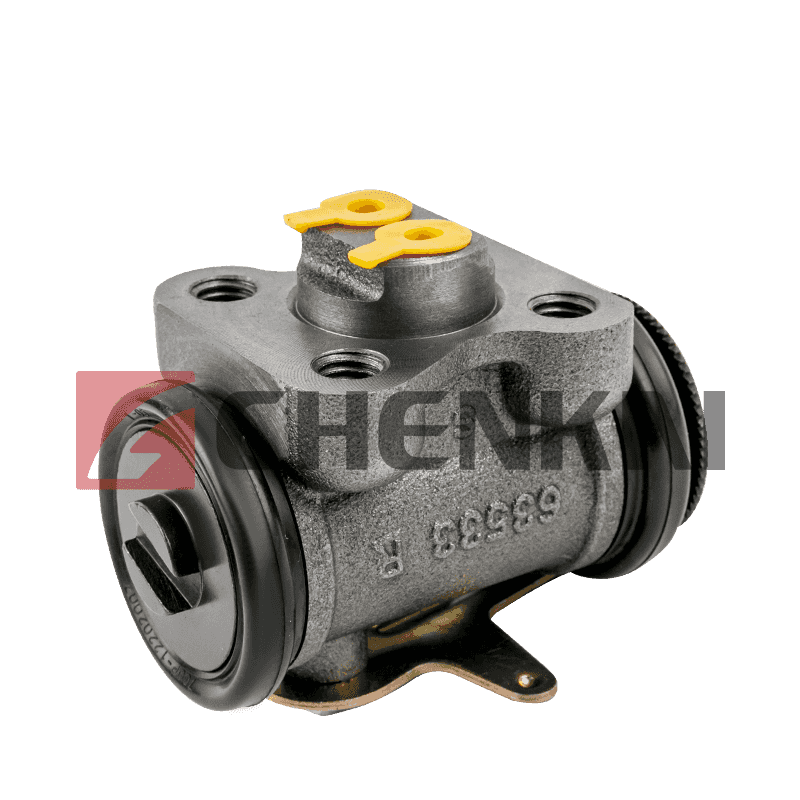

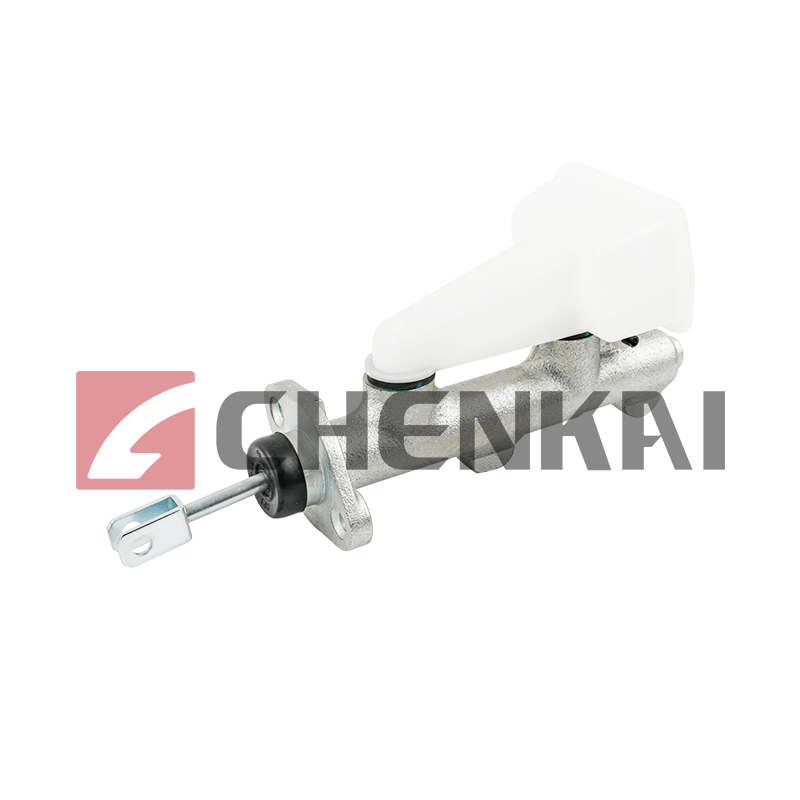

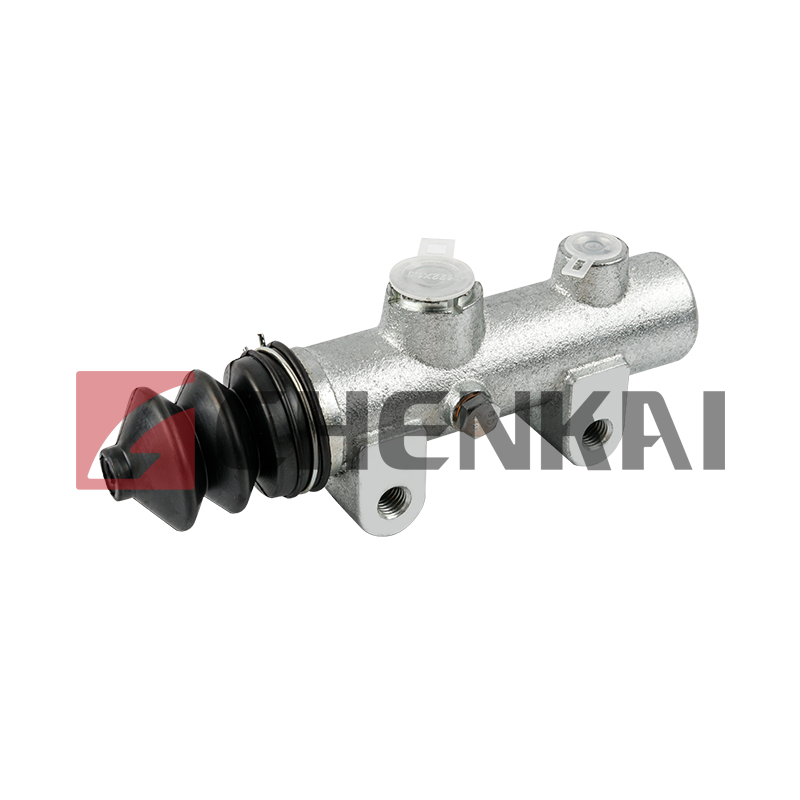

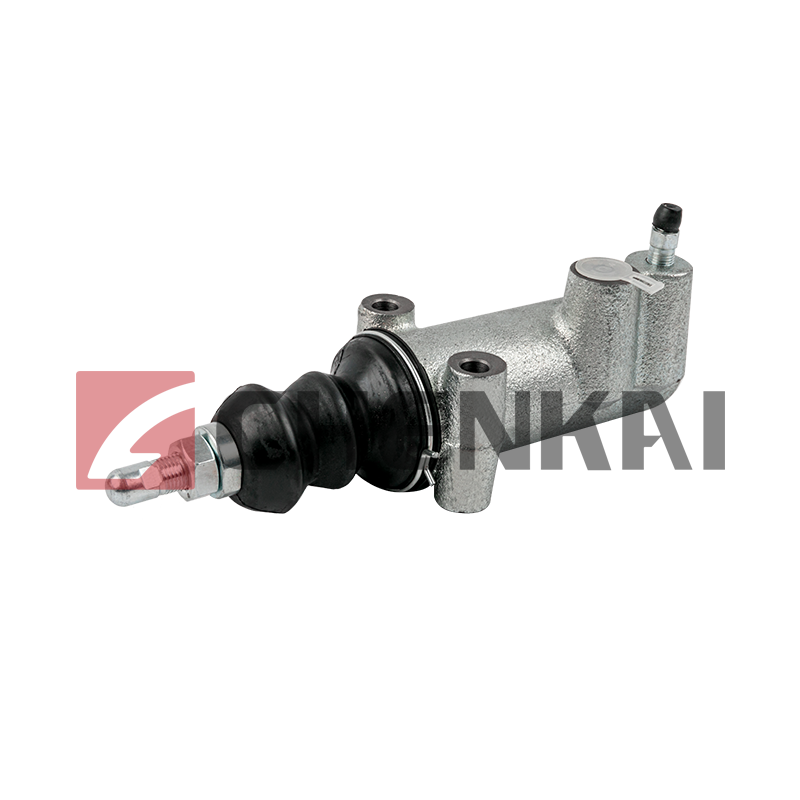

In traditional manual transmissions, a mechanical clutch system was used, consisting of a clutch pedal, clutch master cylinder, release fork, and release bearing. When the driver pressed the clutch pedal, the master cylinder generated hydraulic pressure, which, in turn, activated the release fork, disengaging the clutch and allowing the driver to change gears.

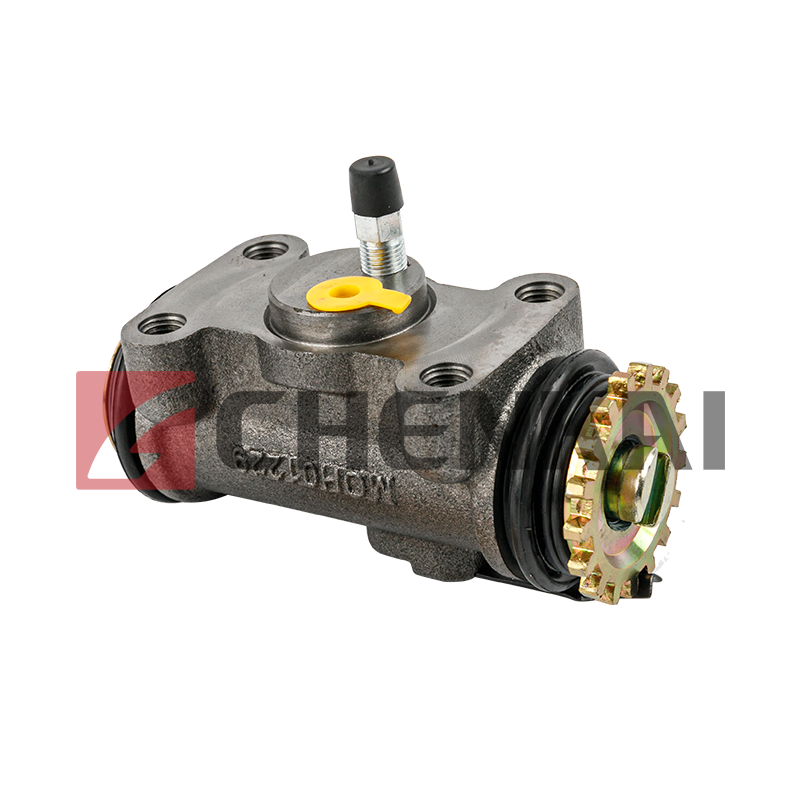

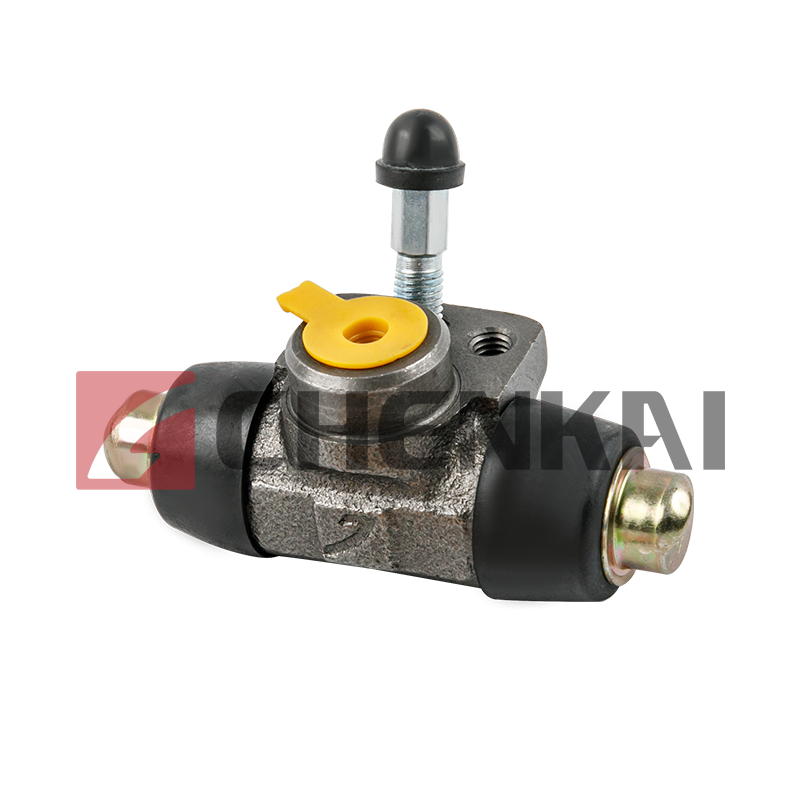

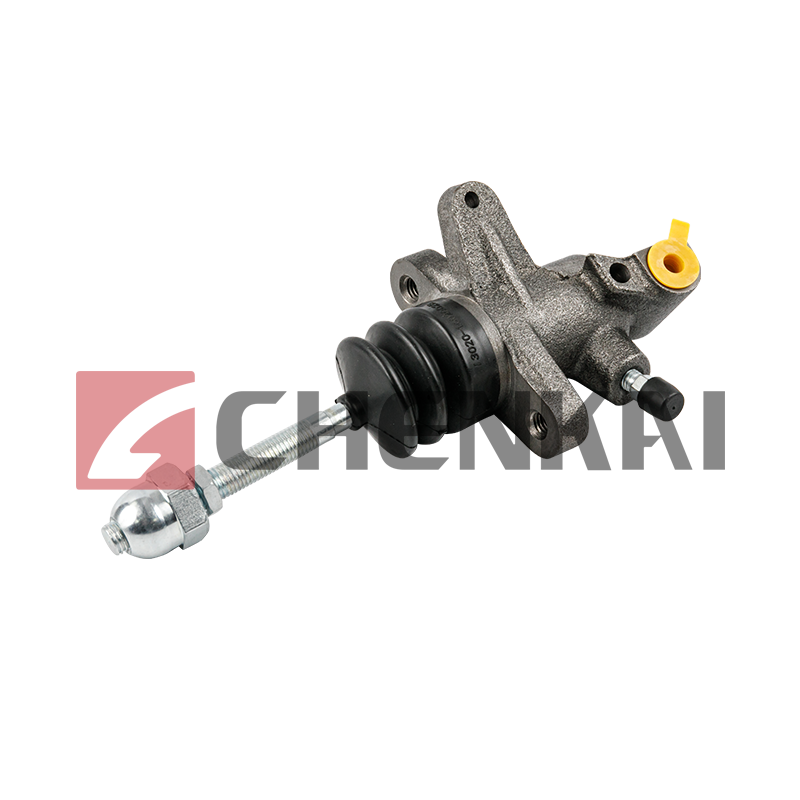

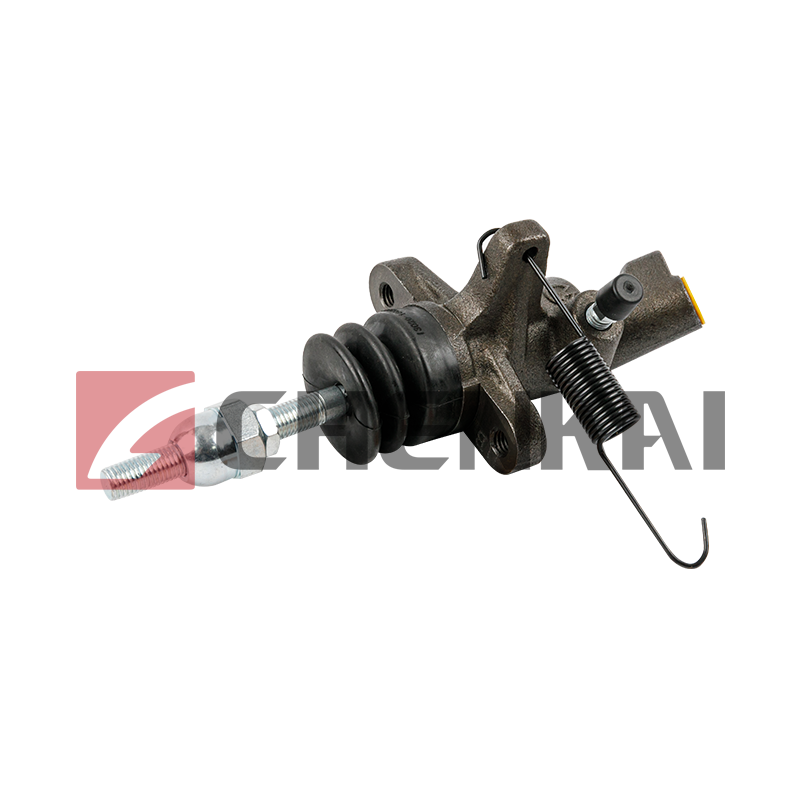

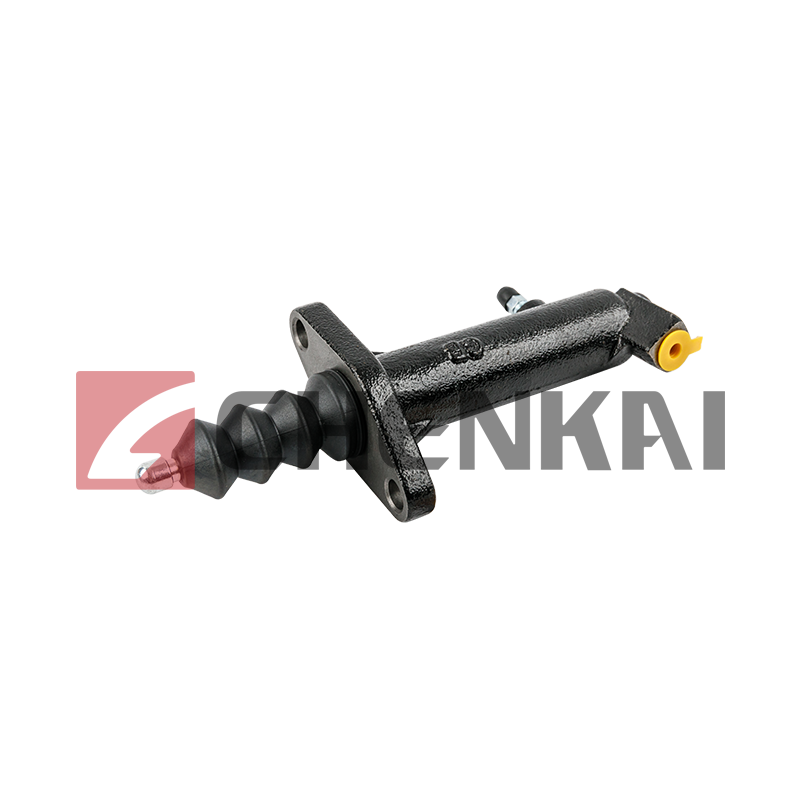

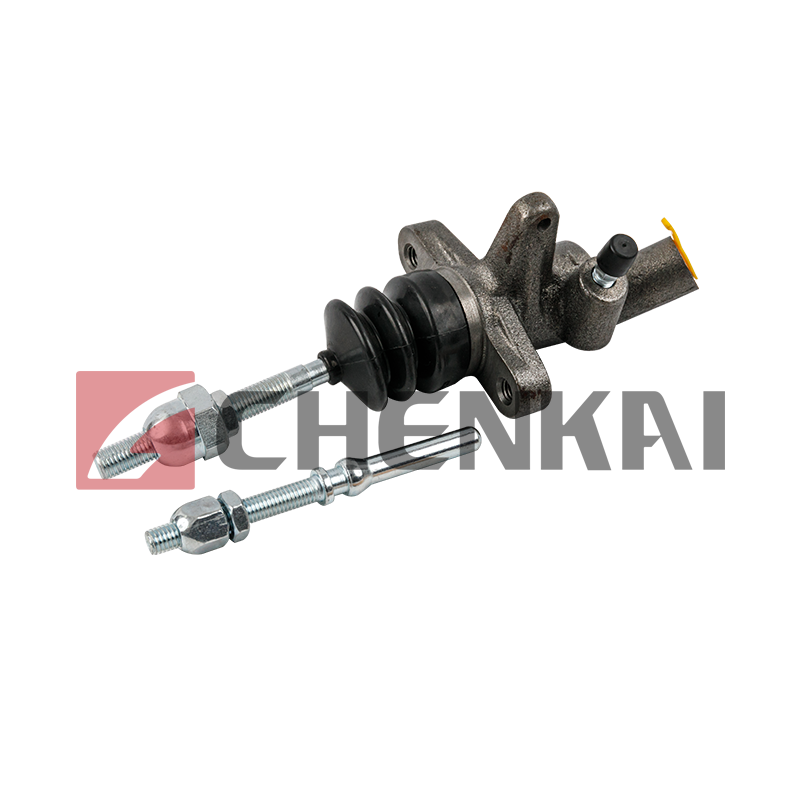

Hydraulic clutch release bearings (HCRBs) introduced a more efficient and reliable way of disengaging the clutch. Instead of using the traditional mechanical linkage, an HCRB directly interacts with the clutch diaphragm spring, which controls the engagement and disengagement of the clutch.

Here's how the HCRB functions:

Hydraulic Actuation: When the driver presses the clutch pedal, hydraulic pressure is generated in the master cylinder, transmitting this pressure through a hydraulic line to the HCRB.

Concentric Design: The HCRB has a concentric design, which means it surrounds the transmission input shaft and makes direct contact with the clutch diaphragm spring.

Clutch Disengagement: The hydraulic pressure received by the HCRB causes the bearing to move forward, pushing on the clutch diaphragm spring. This action releases the pressure on the clutch disc, disengaging it from the flywheel. Consequently, power transfer between the engine and the transmission is interrupted, allowing smooth gear changes.

Benefits of Hydraulic Clutch Release Bearings:

Improved Pedal Feel: HCRBs offer better pedal feel and smoother clutch engagement due to their hydraulic actuation, making gear shifting more comfortable for the driver.

Reduced Pedal Effort: Compared to traditional mechanical clutch systems, HCRBs generally require less pedal effort, reducing driver fatigue in heavy traffic conditions.

Precise Clutch Control: The hydraulic actuation allows for more precise control over the clutch engagement point, resulting in smoother gear shifts and better overall drivability.

Longevity and Reliability: Hydraulic systems tend to experience less wear and tear than mechanical linkages, leading to increased longevity and improved reliability of the clutch system.

Integration with Dual-Clutch Transmissions: HCRBs are often used in dual-clutch transmissions (DCTs) due to their precise control and responsiveness, contributing to the advancement of DCT technology.

Overall, hydraulic clutch release bearings have played a vital role in revolutionizing automotive transmissions by providing enhanced performance, efficiency, and reliability to manual and dual-clutch transmission systems. Their adoption has led to better driving experiences for consumers and continues to be a significant area of development in the automotive industry.

English

English русский

русский Español

Español