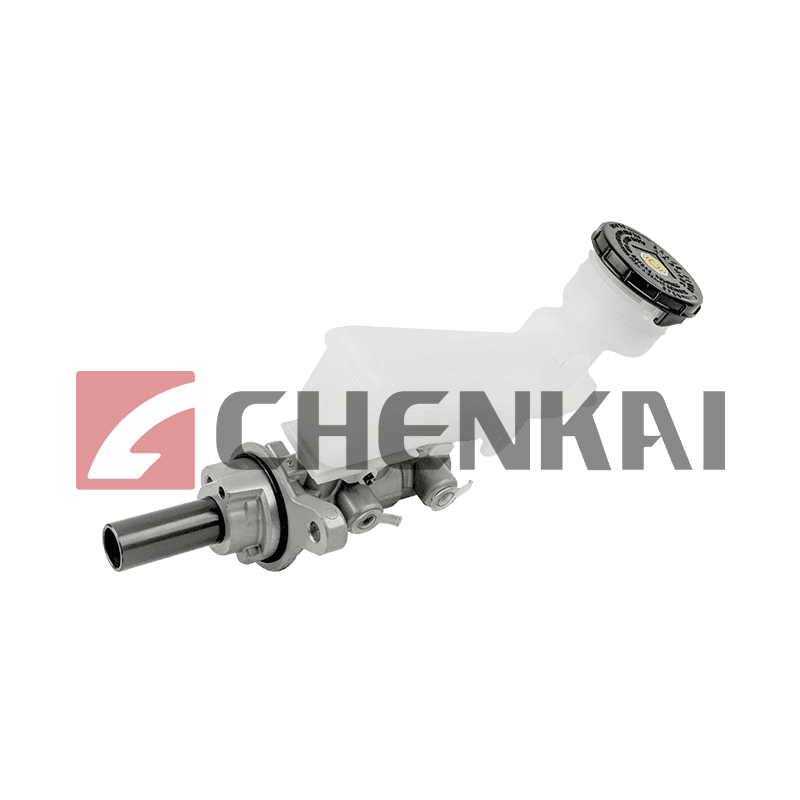

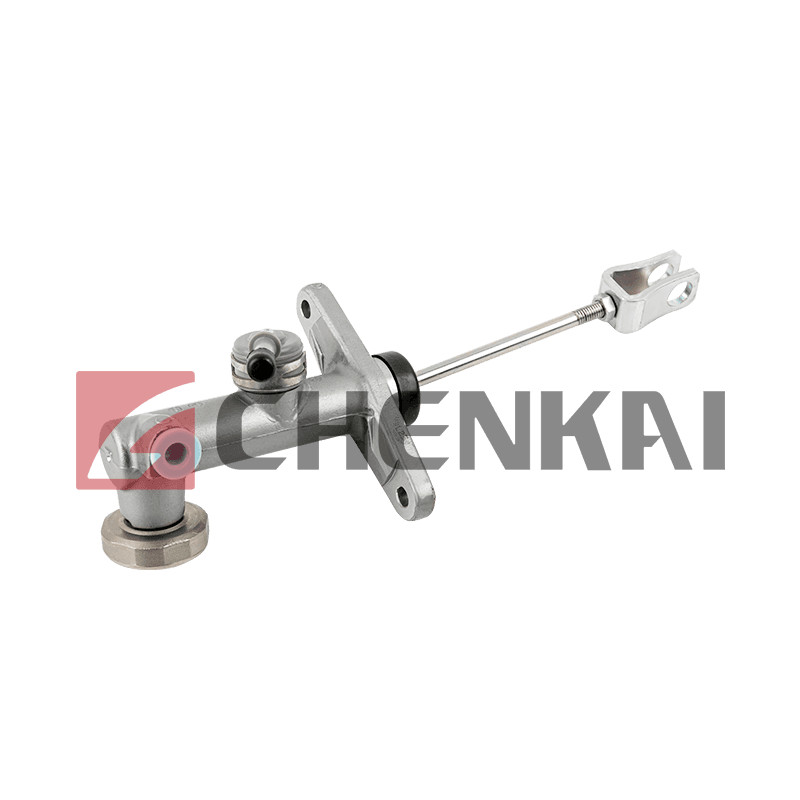

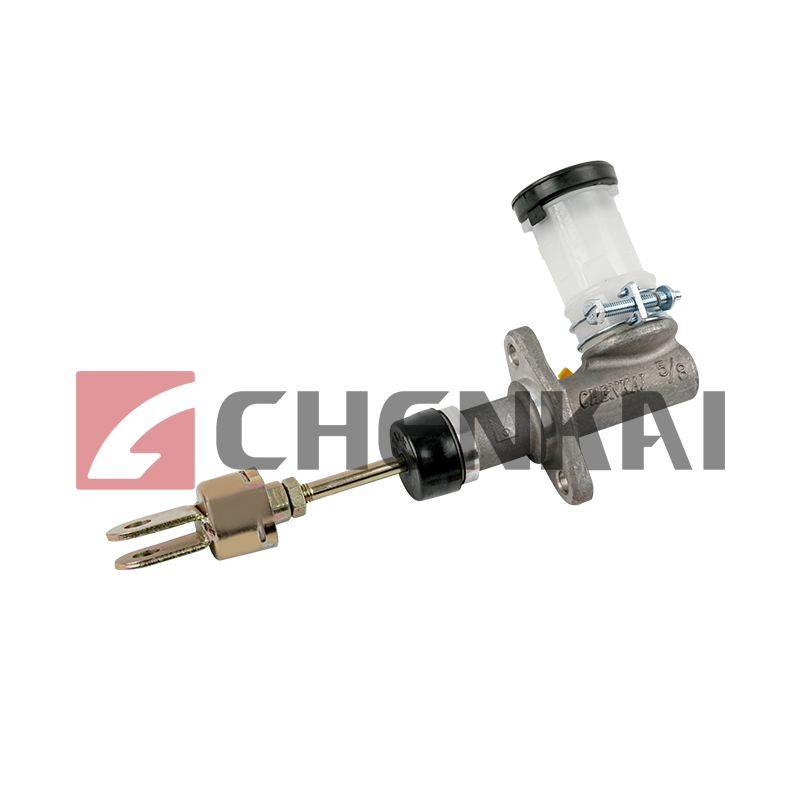

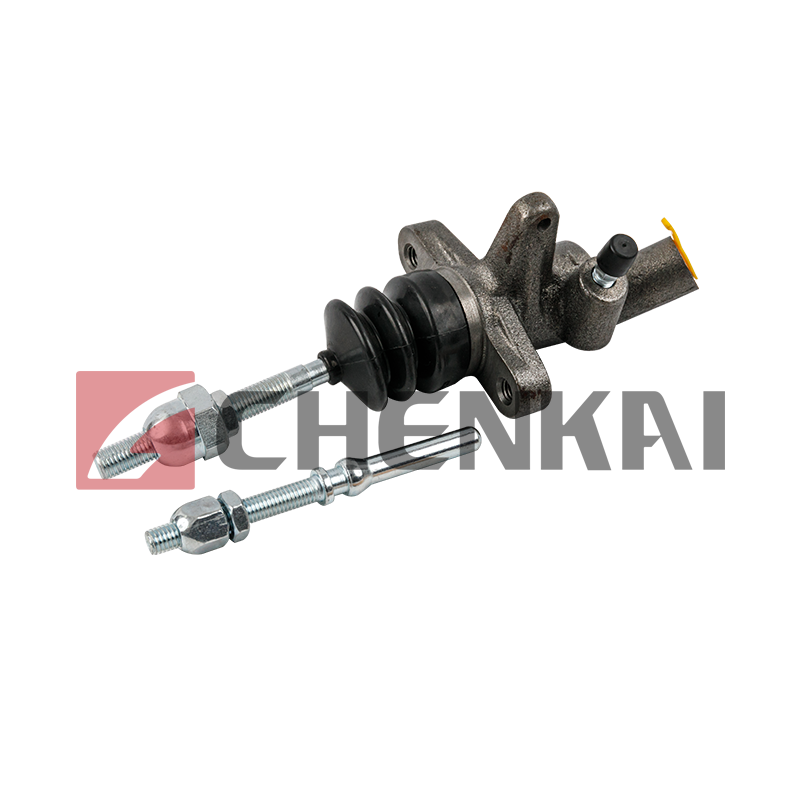

The 47500-407 clutch master cylinder is a key component in the automotive clutch system. Its working principle involves the transmission and control of hydraulic pressure to ensure smooth driving and shifting operations of the vehicle. The following is a detailed explanation of the working principle of the 47500-407 clutch master cylinder.

1. Hydraulic transmission system: The working principle of the 47500-407 clutch master cylinder is based on the hydraulic transmission system. In the clutch system, hydraulic pressure is used to control the opening and closing state of the clutch. The hydraulic transmission system consists of a hydraulic oil tank, a hydraulic pump, an oil pipeline, a hydraulic cylinder, etc.

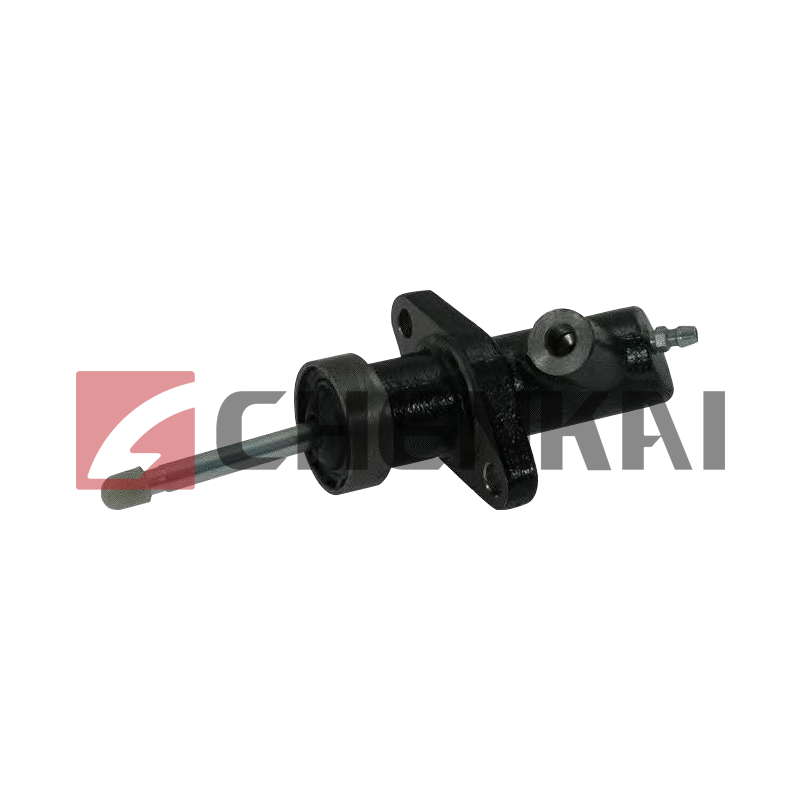

2. Function of the hydraulic pump: The hydraulic pump in the clutch master cylinder is responsible for extracting hydraulic oil from the tank and generating high pressure to transfer the hydraulic oil to the clutch system. The hydraulic pump is usually driven by the engine and its operation is controlled by the clutch pedal.

3. Storage and supply of hydraulic oil: Hydraulic oil is stored in the hydraulic oil tank, drawn through a pump and sent to the clutch system. The pressure of hydraulic oil in the system is controlled by the work of the hydraulic pump and the feedback of the hydraulic cylinder to ensure that there is always sufficient hydraulic pressure in the system.

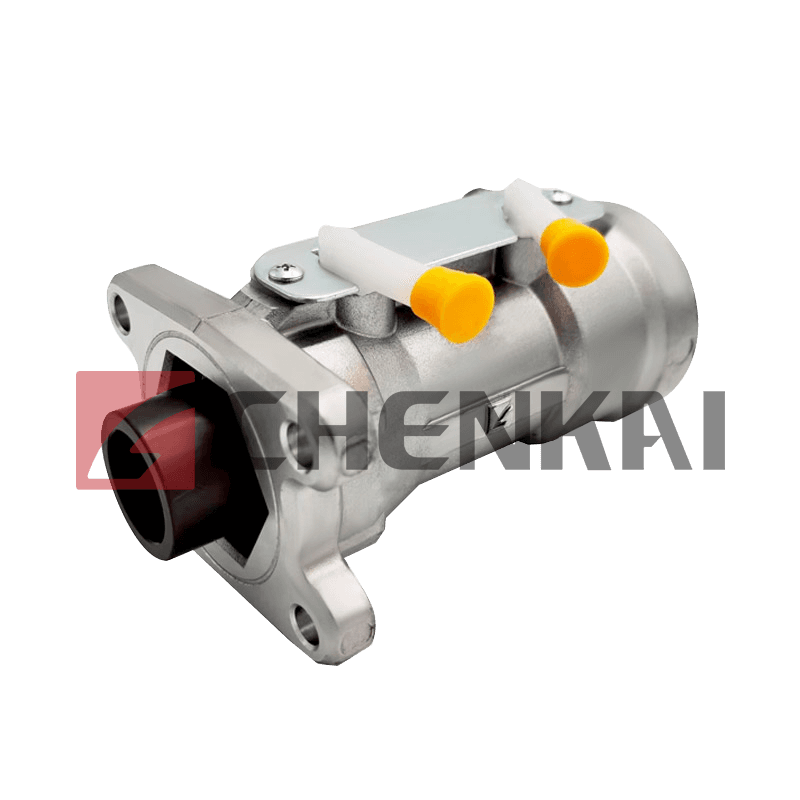

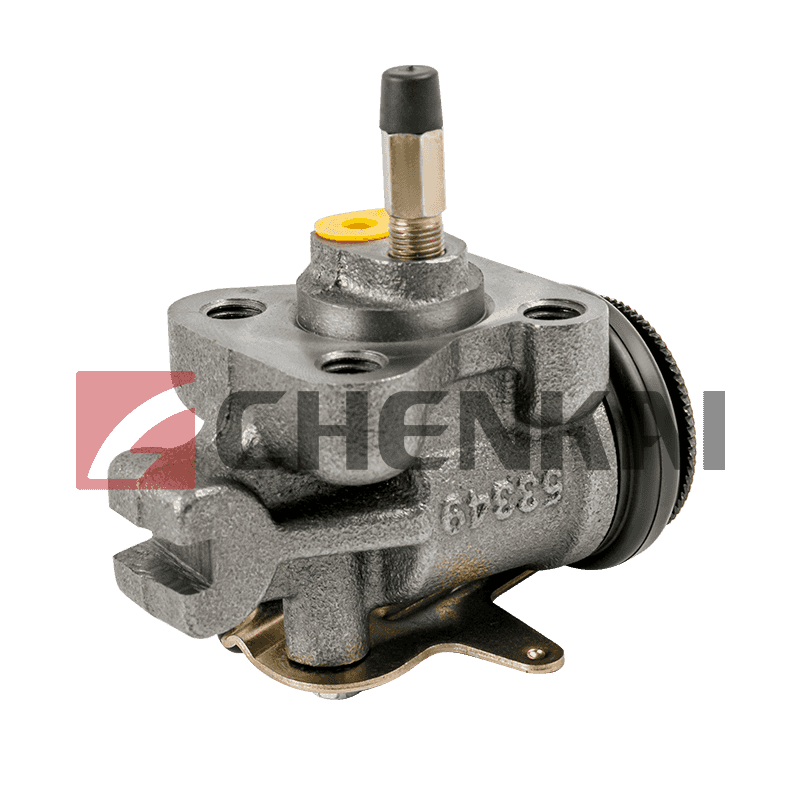

4. The function of the hydraulic cylinder: The hydraulic cylinder is one of the key components in the clutch master cylinder. Its function is to control the opening and closing of the clutch based on changes in hydraulic pressure. When the hydraulic pump provides sufficient pressure, the piston in the hydraulic cylinder will move and push the clutch separator or pressure plate to achieve the clutch disengagement state.

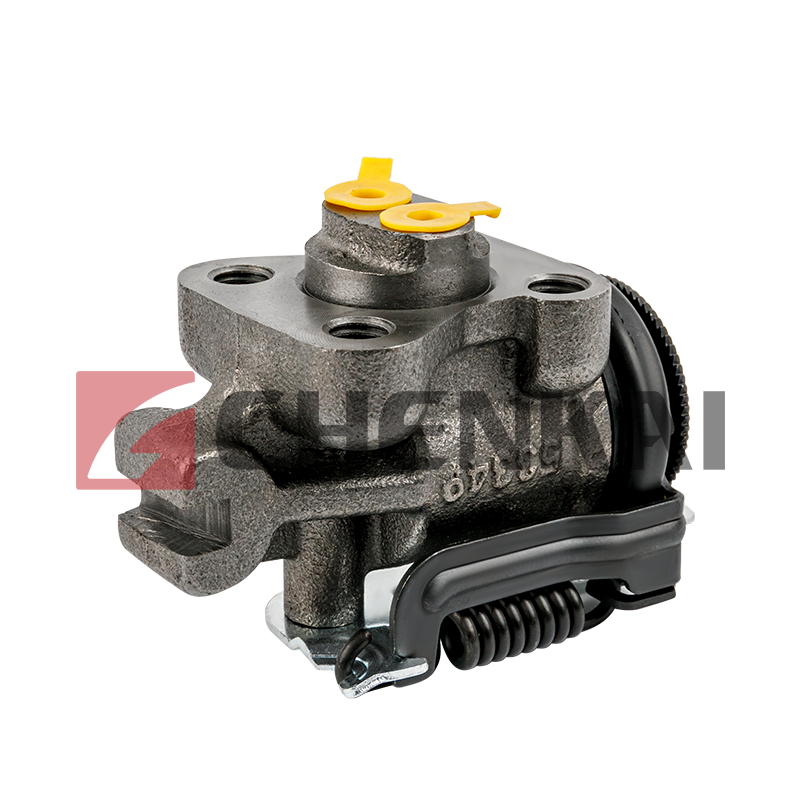

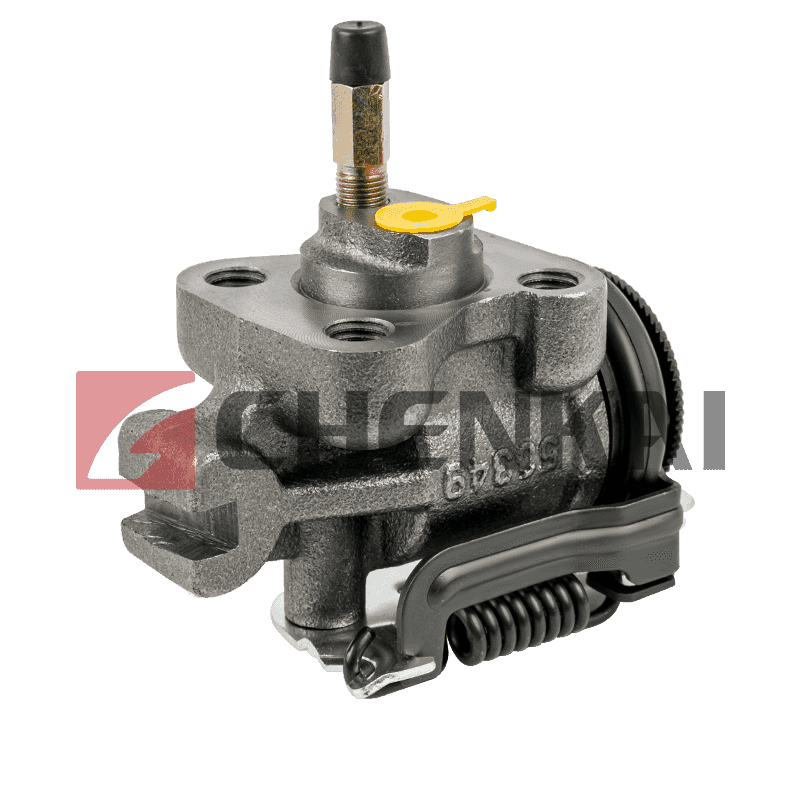

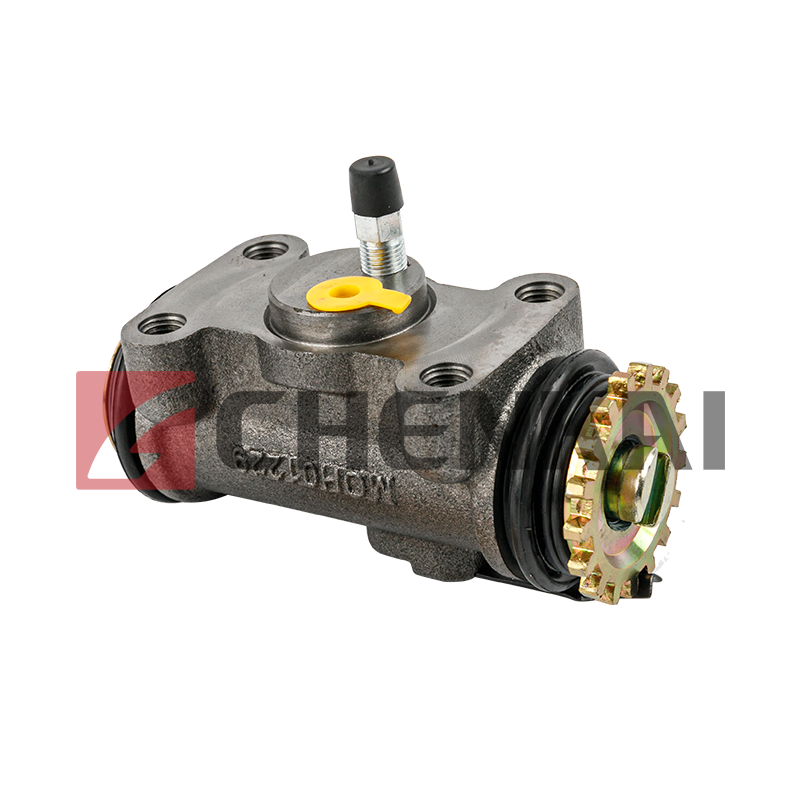

5. Clutch opening and closing control: Controlling the clutch opening and closing status is achieved through the hydraulic valve and pedal position sensor in the hydraulic system. The hydraulic valve adjusts the output of the hydraulic pump according to the degree of pedal depression, thereby controlling the change in hydraulic pressure in the hydraulic cylinder, and thereby controlling the opening and closing of the clutch.

6. Work flow: When the driver depresses the clutch pedal, the hydraulic valve senses the position change of the pedal and adjusts the output of the hydraulic pump. The hydraulic pump provides high-pressure hydraulic oil, which is delivered to the hydraulic cylinder through the oil pipe. The piston of the hydraulic cylinder moves, pushing the clutch separator or pressure plate, causing the clutch to disengage. On the contrary, when the driver releases the clutch pedal, the hydraulic system decompresses and the hydraulic cylinder piston returns, closing the clutch and realizing the gear shifting operation.

7. Safety protection: 47500-407 clutch master cylinder usually also contains safety protection devices, such as overload protection, temperature protection, etc., to ensure that the system can work normally under harsh conditions and prevent damage caused by excessive pressure or temperature.

English

English русский

русский Español

Español