Brake Pads Installation

Equipment Needed

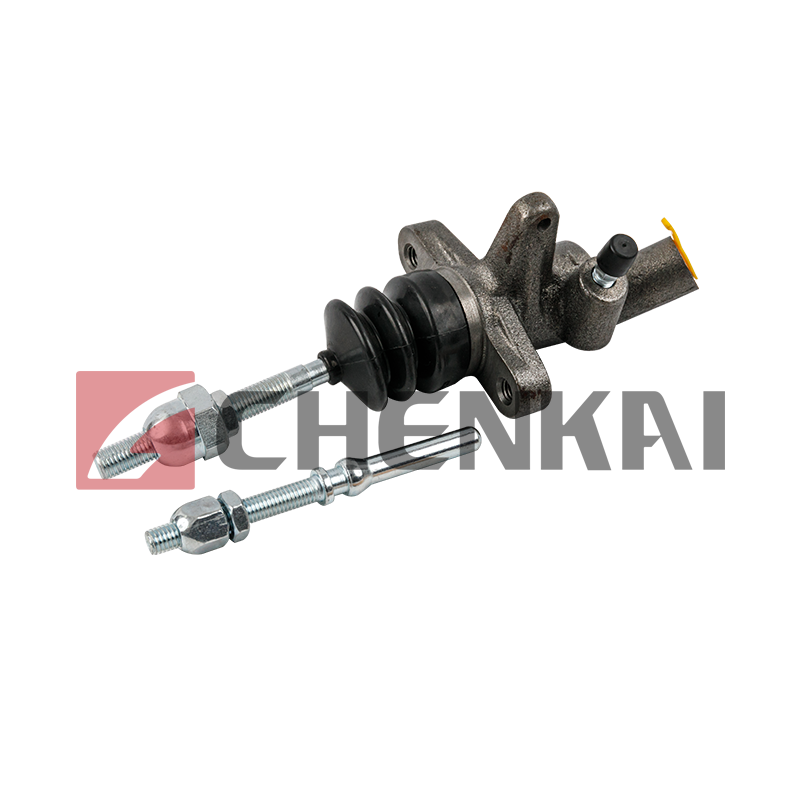

New CHENKAI OE Replacement Brake Pad set

New brake pad hardware kit

High Temperature Lubricant

New discs (If required)

New wheel bearings /hub assembly (If required)

New brake hoses and lines (If required)

Note: Always renew brake pads in complete sets (e.g. all front pads or all rear pads) to avoid uneven braking.

This installation guide is for reference only. Please refer to the vehicle’s service manual for complete instructions.

Setup

Gather all of the tools and equipment you will need to perform the installation and choose a solid, level place to work.

Step 1 – Remove Your Wheel

Raise your car with a jack using your vehicle manufacturer’s recommended jacking points – see your vehicle handbook or manual. Ensure it is securely supported on a level surface. Place axle stands under the vehicle in addition to the jack for extra safety. Remove the wheels where you’re replacing the brake pads (front or rear). Never work under a vehicle only supported by a jack.

Step 2 – Removing Calipers

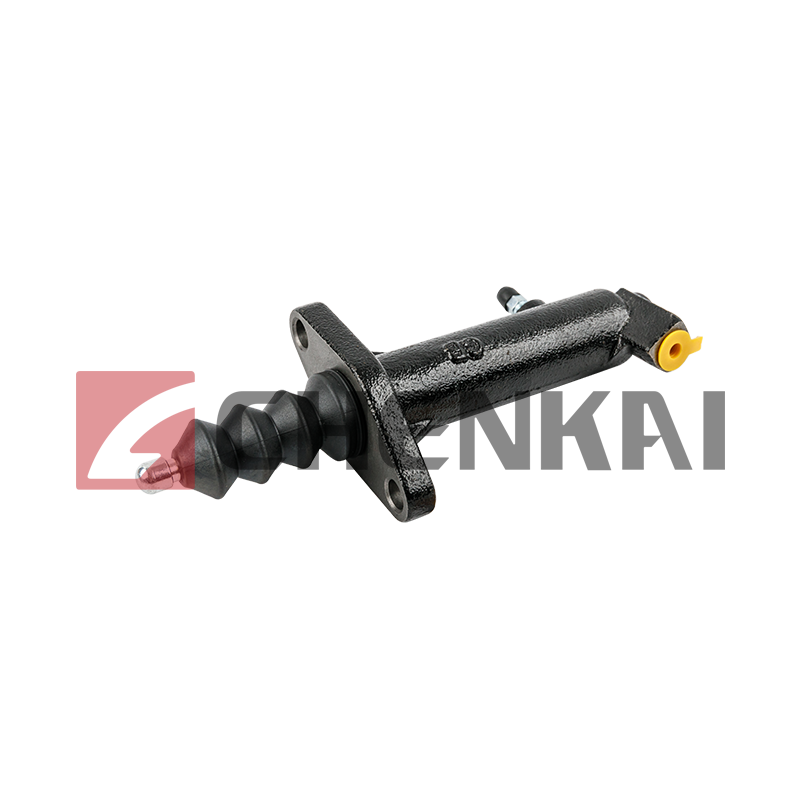

For fixed calipers, remove the caliper mounting bolts only if the pads won’t come out the back of the caliper.

For floating calipers, remove the two caliper mounting bolts or guide pins. Note the location of any bushings or positioner pieces so they can be replaced in their original locations. Lift the caliper off the rotor. Sometimes a twisting motion will push the piston back a bit to give you enough clearance for removal.

For sliding calipers, a support key or retaining clip holds the caliper to the adapter or anchor. Remove the screws or pins holding the key or clip and drive it out. The retainers will lift off when the screws are removed. Note the position of any support springs, anti-rattle springs or clips. Lift the caliper up and off.

Step 3 – Remove the Brake Pads

Push back the piston before removing the old pads.

For fixed calipers, push against the old pads before you remove them. If the caliper must come off, push back one pad at a time until the pistons are seated, after you remove the caliper.

For floating or sliding calipers, you must remove the caliper to push the piston back. Use a large C-clamp and push on the inboard pad.

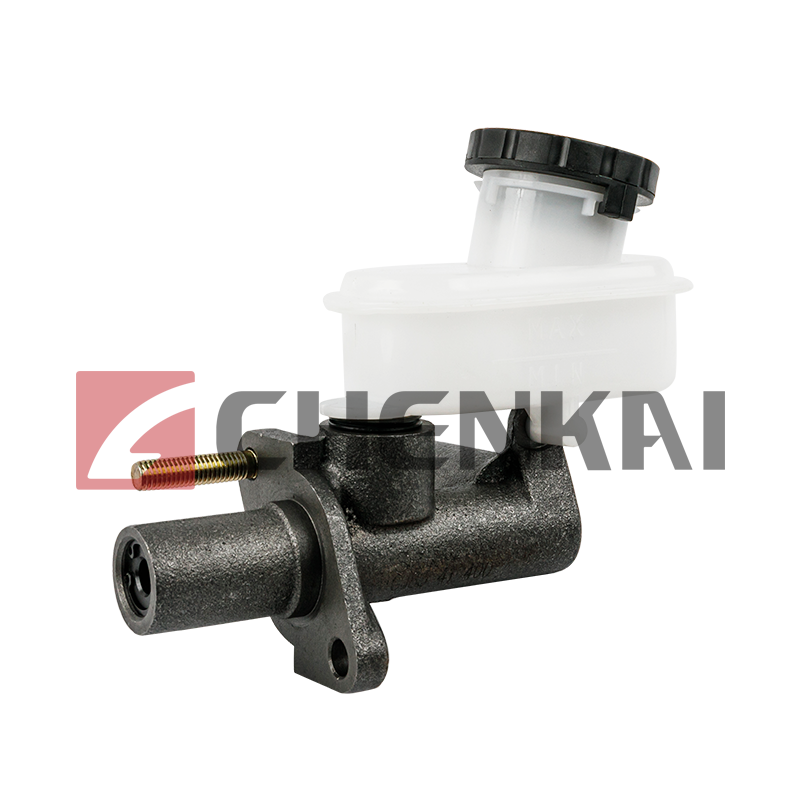

Be careful not to damage the pistons, bores or the dust boots when pushing the pistons back. Do one side at a time and be sure you don’t pop one piston out while pushing on another. Remember to remove half of the brake fluid in the master cylinder before you start.

Check for fluid leaks or rotor scoring and fix them (replace seals/calipers, machine rotors) before going any further. Certain pistons must now be screwed back with an Allen wrench or special tool to seat them.

Step 4 – Check the Brake Disc

Inspect the brake disc. If there’s any scoring, you need to get that replaced too.

Step 5 – Fit Brake Pads

Install the new pads in the caliper or anchor in the reverse order of their removal. Make sure all locating clips or anti-rattle springs are in position. Some outboard pads have “ears” that must be bent to fit tightly on the caliper. If necessary, bend the ears by tapping them carefully with a hammer, and use vise grips to press them into position. If the pad is loose on the caliper, it will squeal. DO NOT get grease or oil on the pad linings.

Place the caliper in position and reinstall any bolts, guide pins, support keys or retainers. Some support keys must be hammered into position. Reinstall any retaining screws or pins. Make sure all bushings are in position.

Lightly lubricate all sliding metal surfaces with high temperature lubricant.

Tighten all bolts to factory specifications. NEVER replace bolts or pins with standard hardware. Use only special, high-tensile bolts or pins designed specifically for your vehicle.

Fill the master cylinder with clean disc brake fluid, and bleed the brakes if necessary.

Step 8 – Test Brake Pads

When you’ve done both sides, press the brake pedal a few times to bring the brake pads up to the disc, then check and top up the brake fluid level if necessary. Apply light braking for the first 20 to 30 stops to ensure that the brake pads are properly mated to the brake discs. Additionally avoid hard braking for the first 300 kilometers to ensure that the brake pads do not wear prematurely and provide a long life.

Brake Pads Troubleshooting

|

Symptoms |

Condition Of Pads |

Probable Cause |

Solution |

|

Squealing and grinding |

Glazed / shiny |

Discs below minimum spec or driver abuse |

Replace pads and discs |

|

Weak braking |

Green fade |

Bed in procedure not followed |

Follow correct bedding in procedure |

|

Weak braking and squeal |

Broken pads |

Disc below minimum spec, driver abuse or incorrect fitment |

Replace pads and/or discs |

|

Grinding |

Worn pads |

Pads past service life |

Replace discs and pads |

|

Weak braking |

Brake fluid contamination |

Leaking Caliper, brake hose or fluid contamination during fitment |

Replace pads and fix fluid leak |

|

Premature wear |

Angled or uneven wear |

Caliper seized |

Repair caliper and replace pads |

English

English русский

русский Español

Español