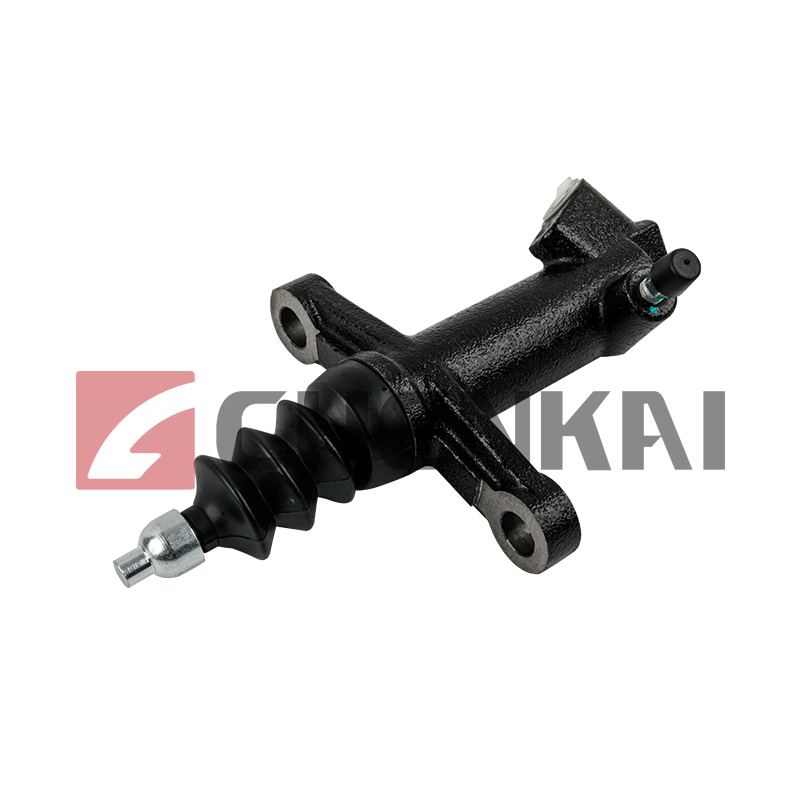

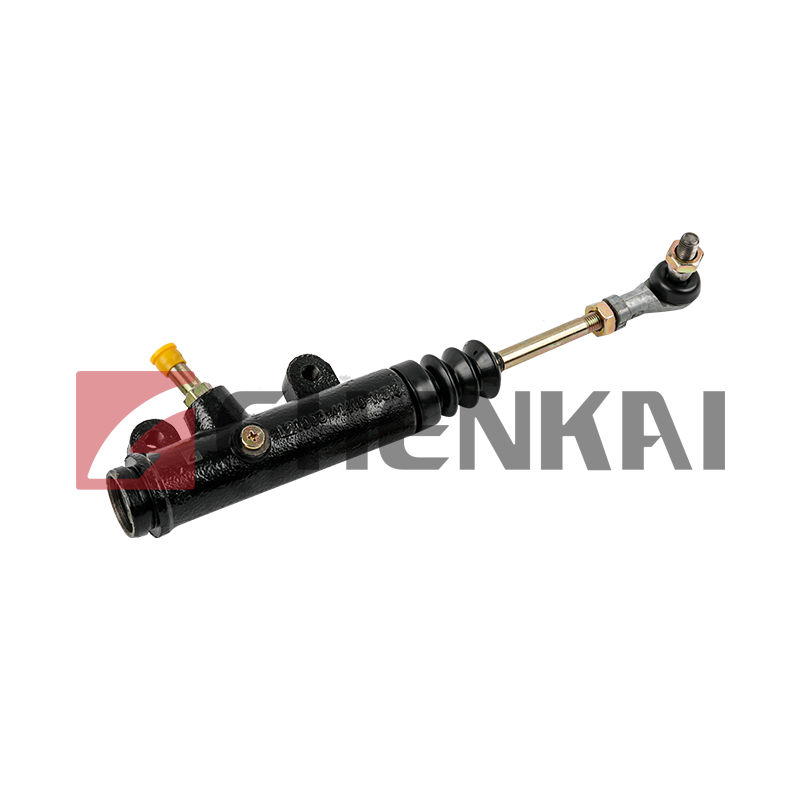

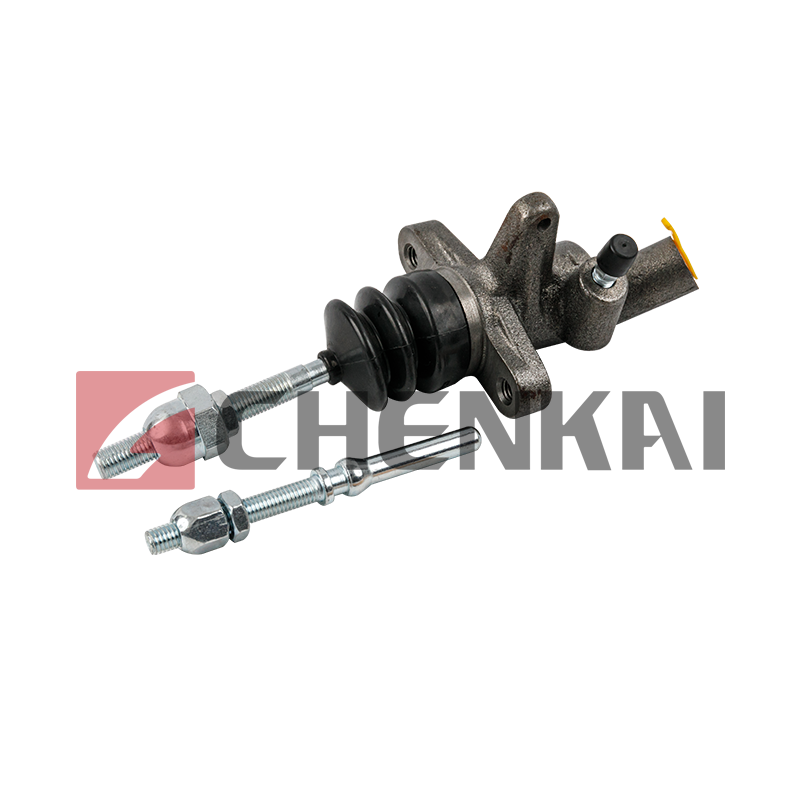

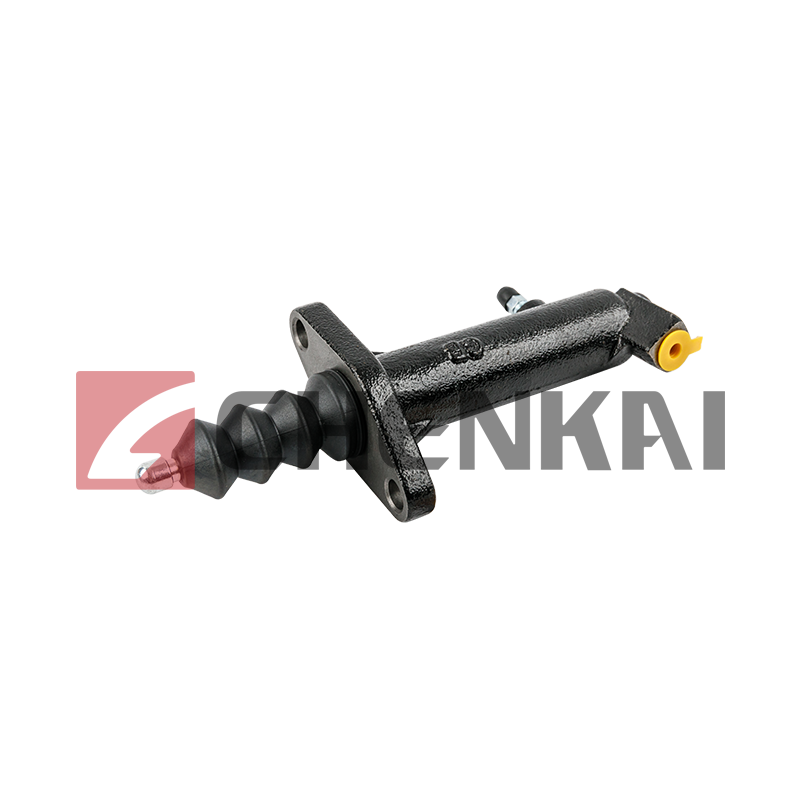

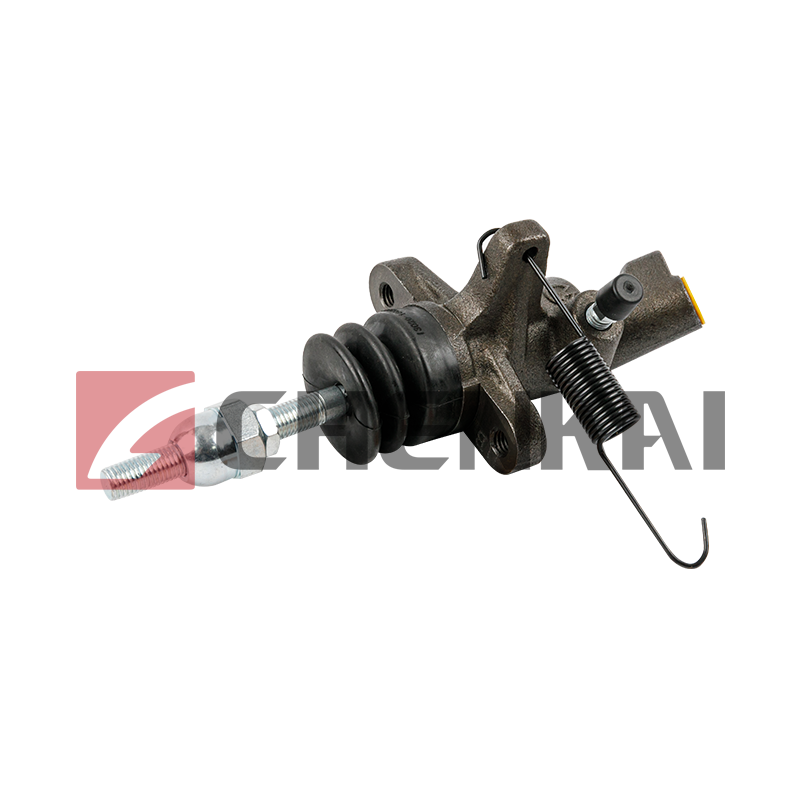

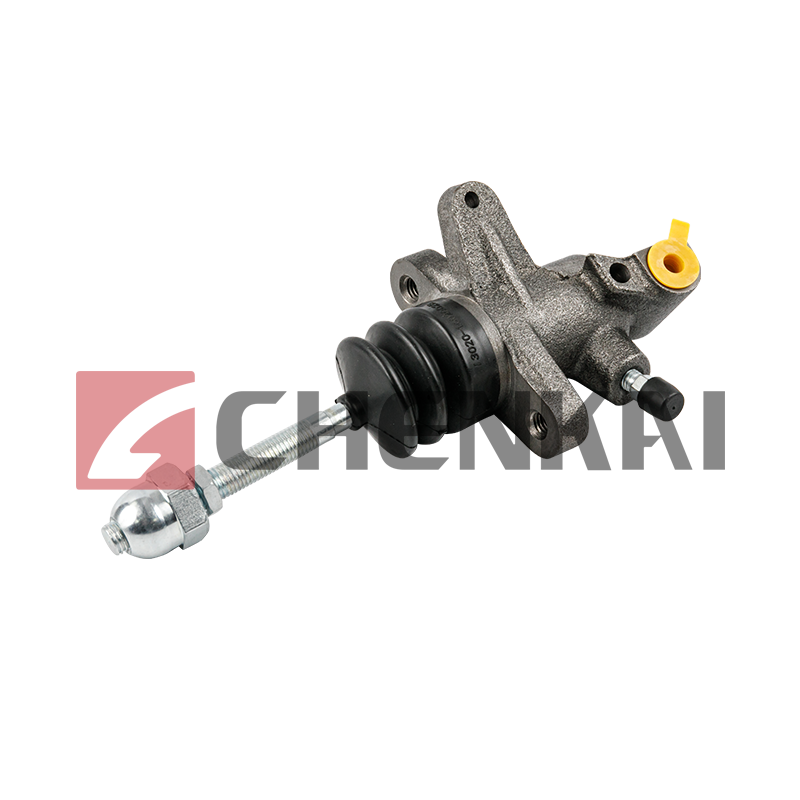

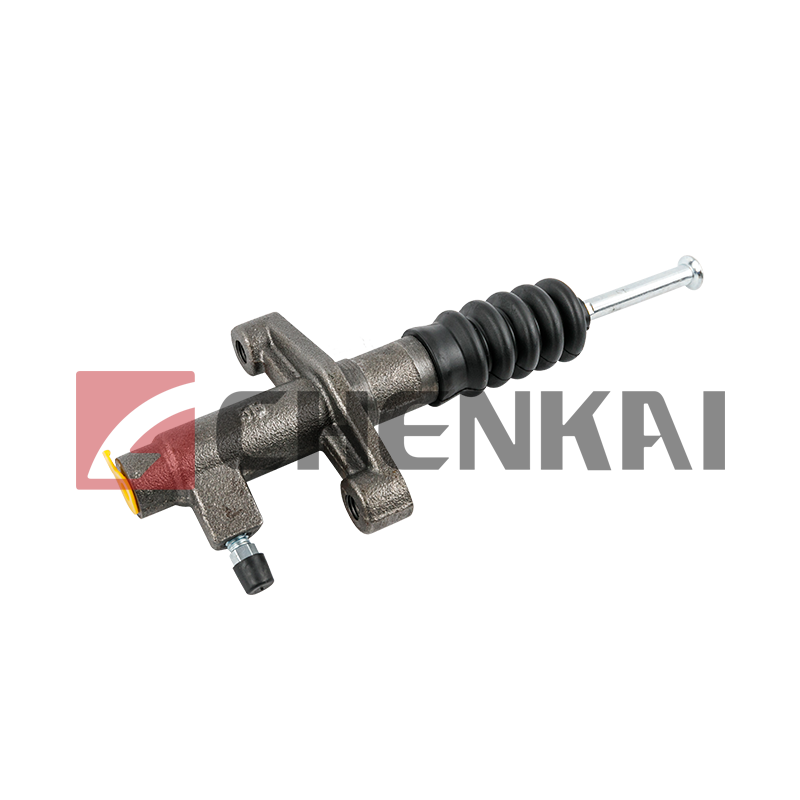

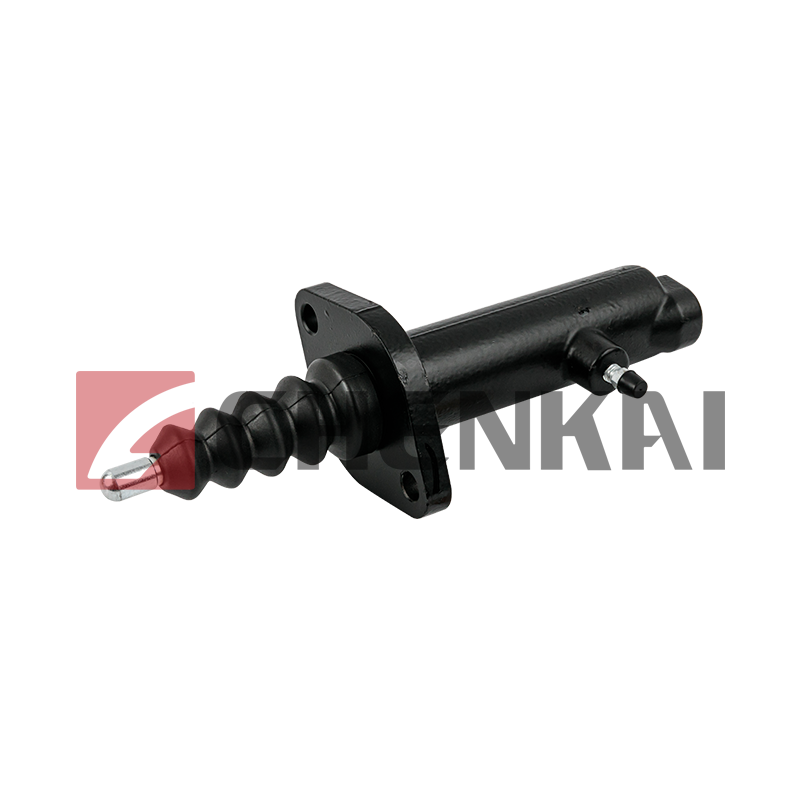

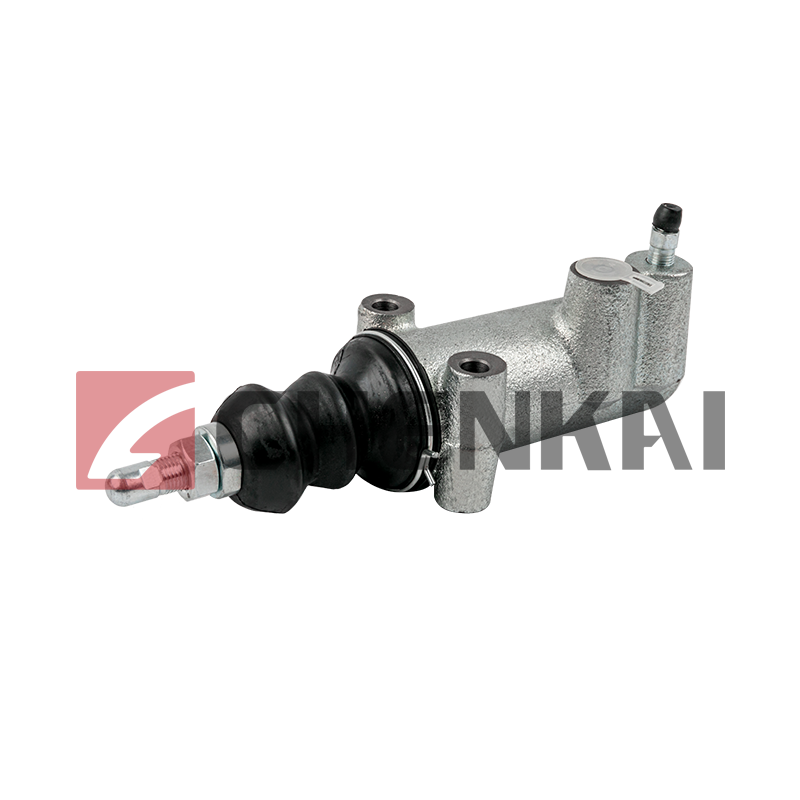

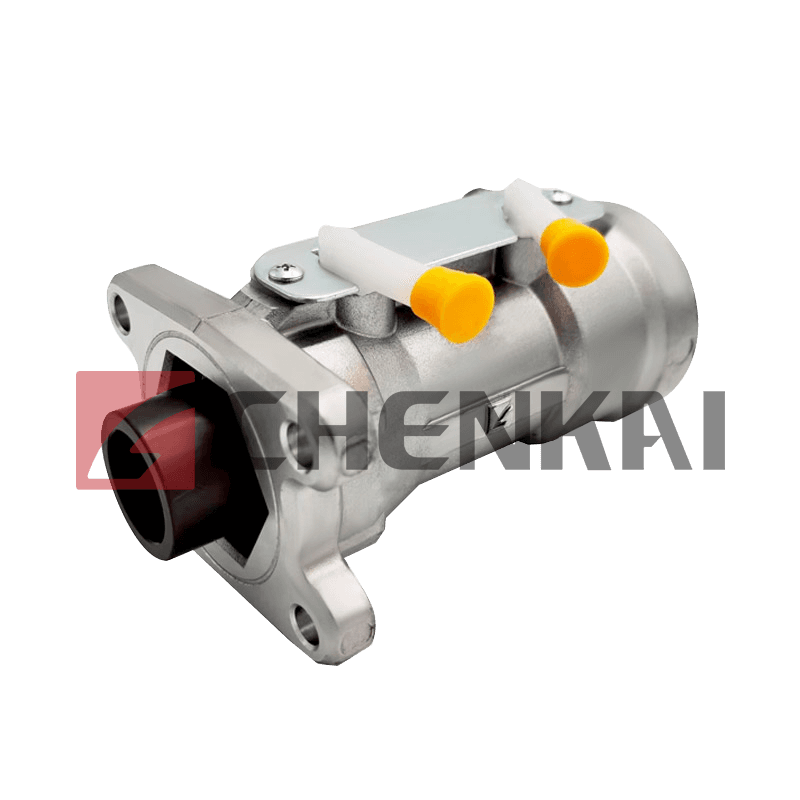

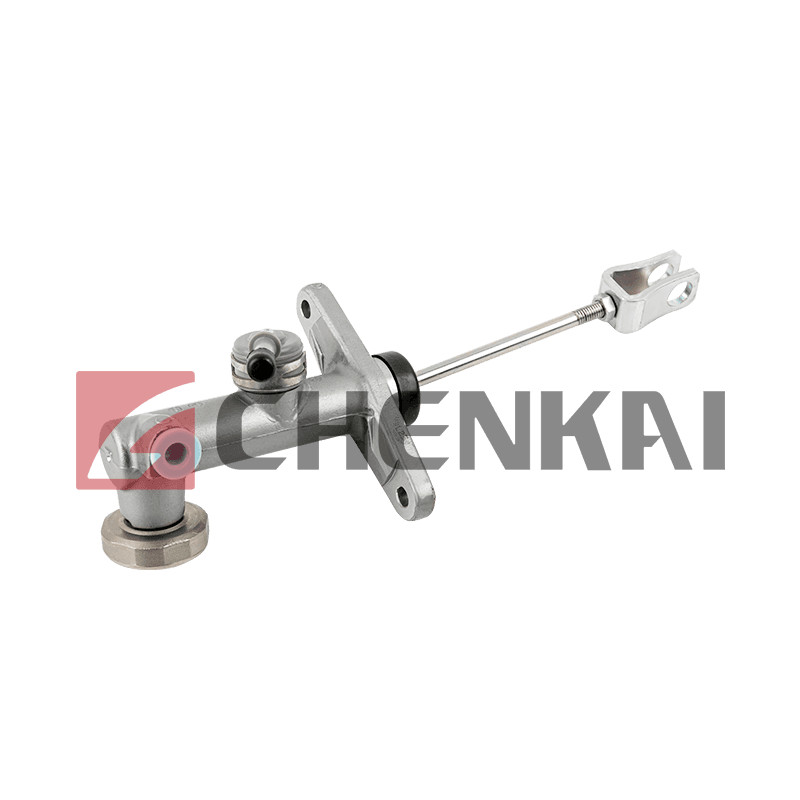

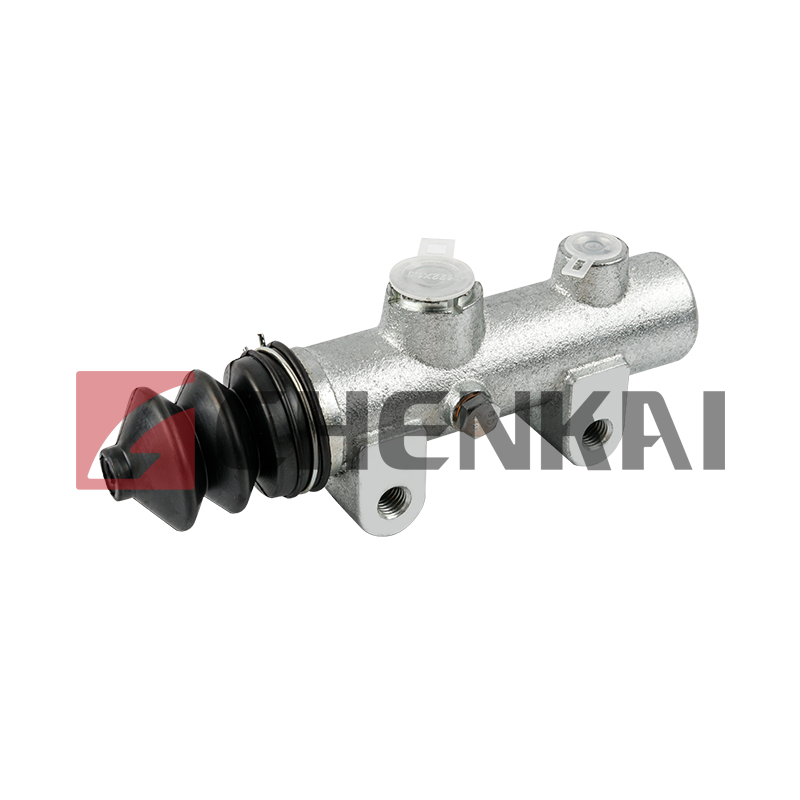

The Role of Clutch Slave Cylinders in Manual Transmission Systems

The

clutch slave cylinder is a crucial component in manual transmission systems. Its primary function is to help engage and disengage the clutch, allowing for smooth gear shifts and control over the power transmission between the engine and the transmission.

Here's how the clutch slave cylinder works and its role in the manual transmission system:

Clutch System Overview:

In a manual transmission system, the clutch is responsible for temporarily disconnecting the engine's power from the transmission, allowing the driver to change gears without damaging the gearbox or stalling the engine. When the clutch pedal is depressed, the clutch is disengaged, and when the pedal is released, the clutch is engaged.

Components of the Clutch System:

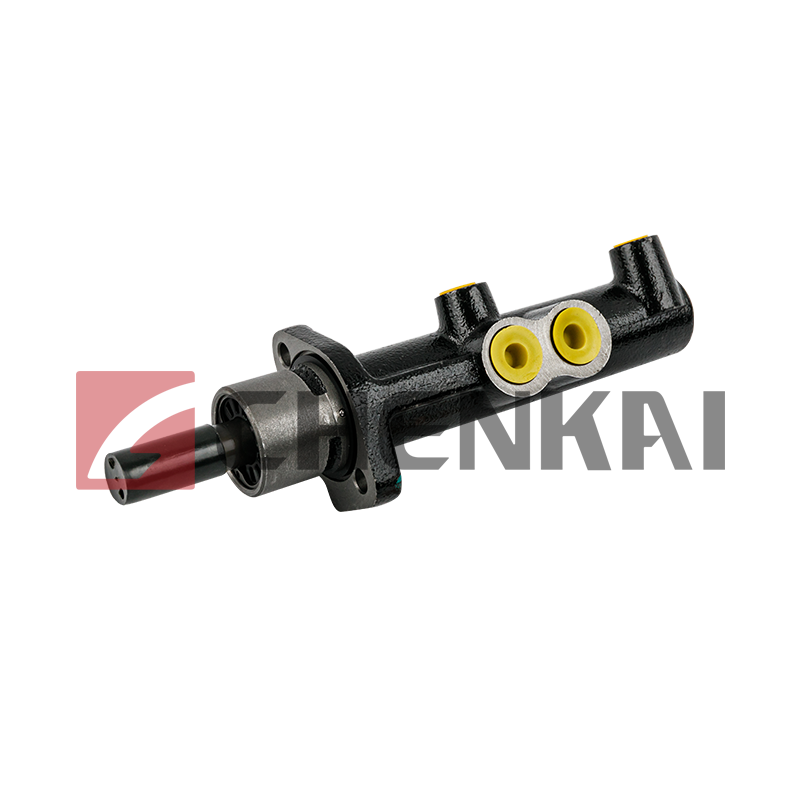

The main components of the clutch system include the clutch pedal, clutch master cylinder, hydraulic lines, clutch slave cylinder, and the clutch itself (usually a friction disc positioned between the engine's flywheel and the transmission's input shaft).

Role of the Clutch Slave Cylinder:

The clutch slave cylinder is a hydraulic device located near the transmission. It is connected to the clutch release fork or actuator arm. When the driver depresses the clutch pedal, hydraulic fluid under pressure is sent from the clutch master cylinder through the hydraulic lines to the clutch slave cylinder.

Clutch Engagement and Disengagement:

When hydraulic fluid enters the clutch slave cylinder, it pushes a piston or a hydraulic actuator. This, in turn, moves the clutch release fork, which applies force to the clutch pressure plate. The pressure plate then releases the clutch disc from the flywheel, disconnecting the engine's power from the transmission. This state is known as "clutch disengaged."

Gear Shifting:

When the driver releases the clutch pedal, the hydraulic pressure in the slave cylinder is released, and the piston or actuator returns to its original position. As a result, the clutch release fork moves the pressure plate back into contact with the clutch disc. This re-engages the clutch, transmitting power from the engine to the transmission, enabling the vehicle to move forward or backward.

Hydraulic System Advantages:

The use of hydraulic fluid in the clutch system provides several advantages. It helps amplify the force applied by the driver on the clutch pedal, making it easier to operate. Additionally, hydraulic systems offer a more consistent and smooth engagement of the clutch compared to mechanical linkages used in older vehicles.

In summary, the clutch slave cylinder plays a vital role in the manual transmission system by converting the driver's input on the clutch pedal into hydraulic pressure to disengage and engage the clutch. This allows for smooth gear shifts, efficient power transmission, and overall better control of the vehicle.

English

English русский

русский Español

Español