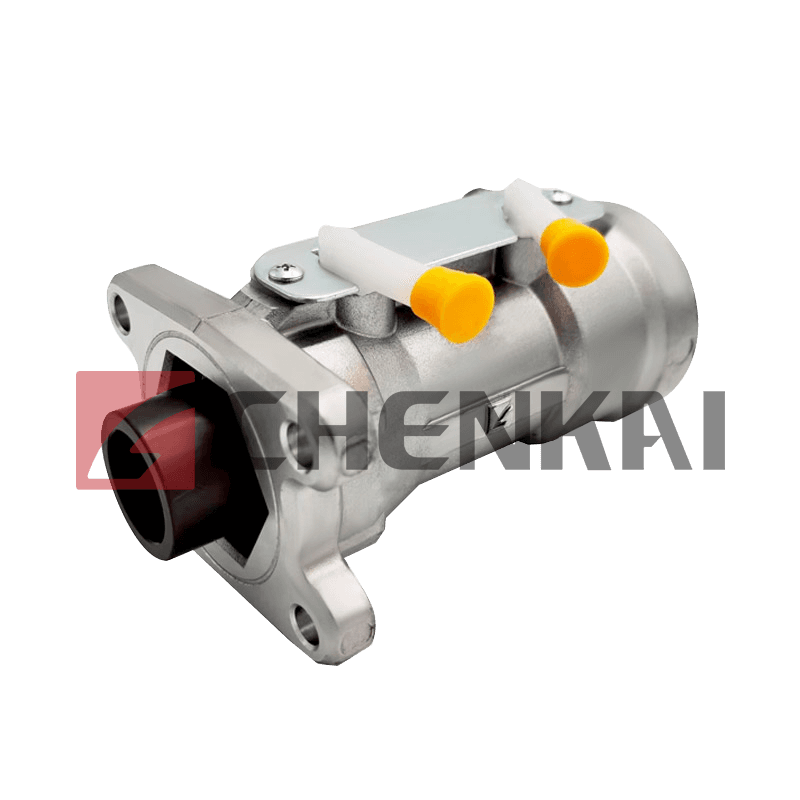

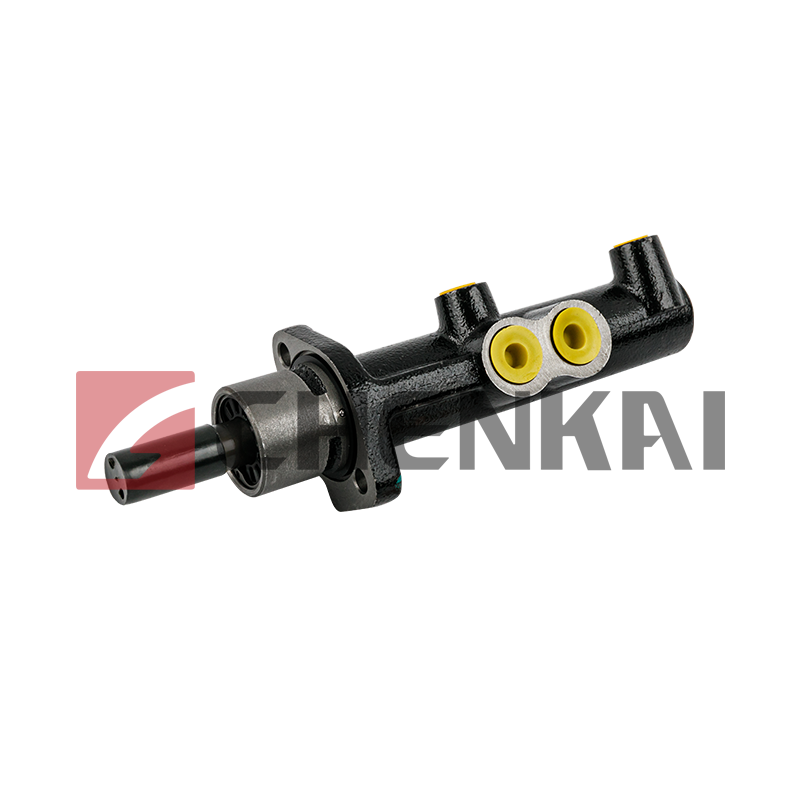

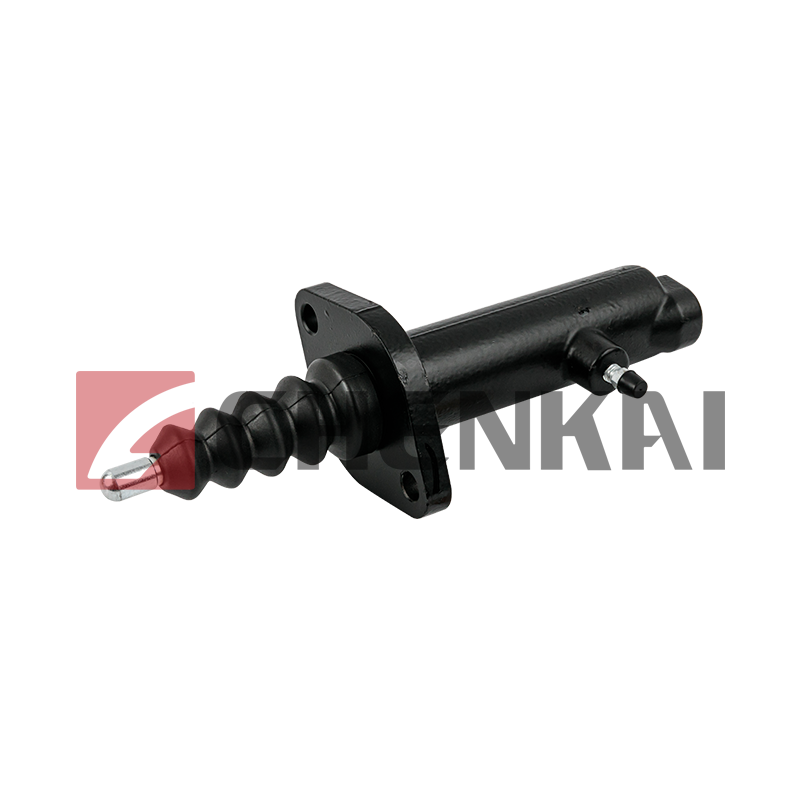

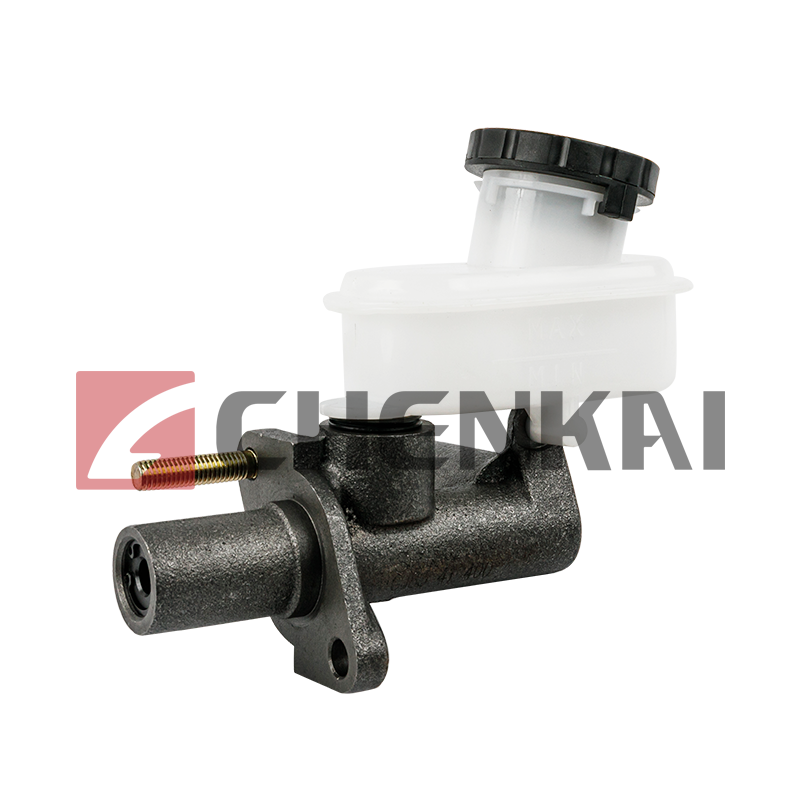

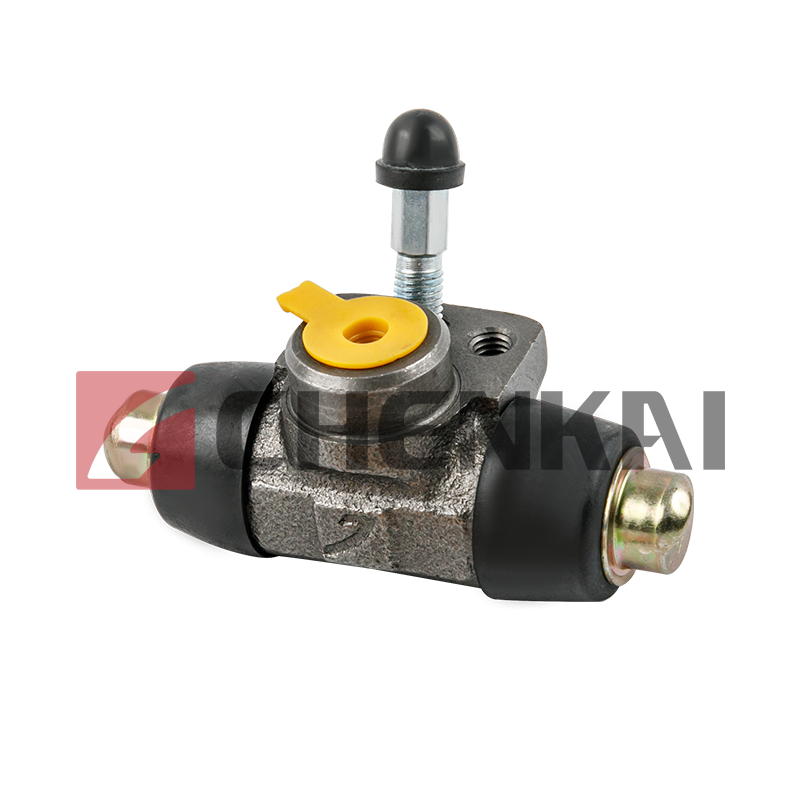

As a key component in the automobile transmission system, the GMC1008 clutch master cylinder performance parameters directly affect the working efficiency of the clutch, the stability of the system and the driving performance of the entire vehicle. For the clutch master cylinder model GMC1008, the following are some key performance parameters:

Working Pressure:

The working pressure is the maximum working pressure of the hydraulic system that the clutch master cylinder can provide. Usually measured in Pascal (Pa) or Bar (bar). High working pressure can ensure the stable operation of the hydraulic system under high load conditions, but too high working pressure may cause system damage or leakage.

Flow Rate:

Flow refers to the amount of hydraulic oil delivered by the clutch master cylinder per unit time, usually expressed in cubic meters per second (m³/s) or liters per minute (L/min). Sufficient flow can ensure that the hydraulic system provides sufficient hydraulic energy in a short time to support quick response and operation of the clutch.

Temperature Range:

The temperature range refers to the temperature range in which the clutch master cylinder can operate normally. The clutch master cylinder usually needs to be able to work under extreme ambient temperature conditions, including high and low temperatures, to ensure that the car can operate normally in various climate conditions.

Viscosity Requirements of hydraulic oil:

The viscosity of hydraulic oil has an important impact on the working effect of the clutch master cylinder. Appropriate hydraulic oil viscosity can ensure the lubrication effect and transmission efficiency of the hydraulic system, and improve the stability and reliability of the system.

Response Time:

Response time refers to the time it takes for the clutch master cylinder to take action after receiving the signal. The shorter the response time, the stronger the system's control capabilities and driving responsiveness. For high-performance vehicles, fast response times improve the driving experience and handling.

Noise Level:

Noise level refers to the amount of noise produced by the clutch master cylinder when it is operating. Low noise levels can improve the vehicle's driving comfort and riding experience and reduce driver fatigue.

Reliability and Durability:

The reliability and durability of the clutch master cylinder are one of its most important performance indicators. An excellent clutch master cylinder should have stable performance, long working life, anti-wear and anti-corrosion properties, and be able to maintain stable operation in harsh working environments.

Size and Weight:

The size and weight of the clutch master cylinder directly affect the design and performance of the vehicle. A smaller and lighter clutch master cylinder can reduce the overall weight and fuel consumption of the vehicle, and improve the vehicle's fuel economy and handling performance.

+ 86 139 5828 3988

+ 86 139 5828 3988 + 86 (0) 574 63574223

+ 86 (0) 574 63574223

Web Menu

Product Search

Exit Menu

Industry News

Home / News / Industry News / What are the key performance parameters of the GMC1008 clutch master cylinder?

What are the key performance parameters of the GMC1008 clutch master cylinder?

PREV:What impact does the clutch slave cylinder have on vehicle fuel efficiency?NEXT:What role does the clutch master cylinder play in the automotive transmission system?

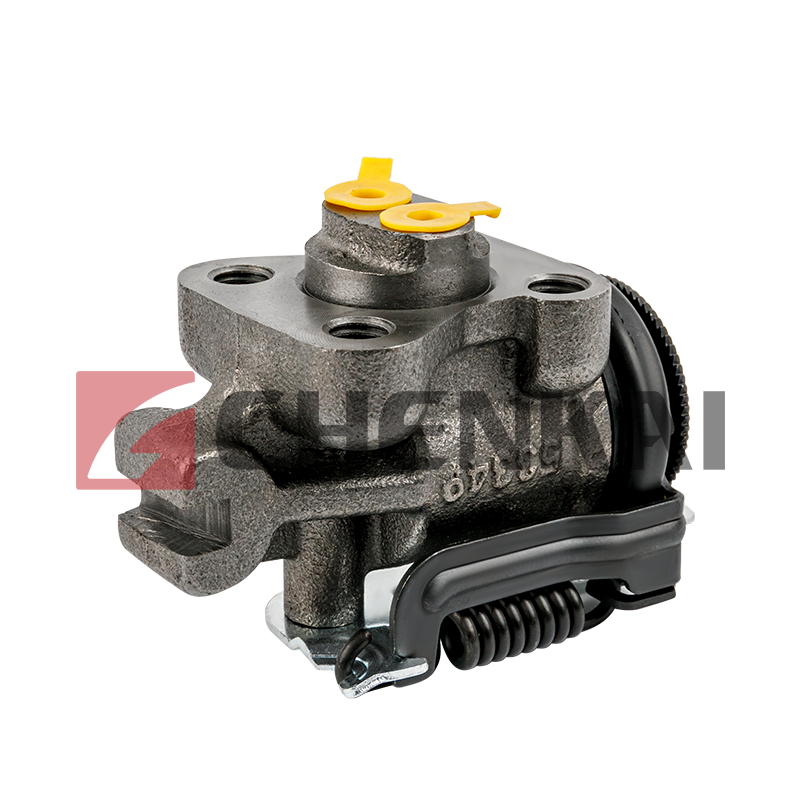

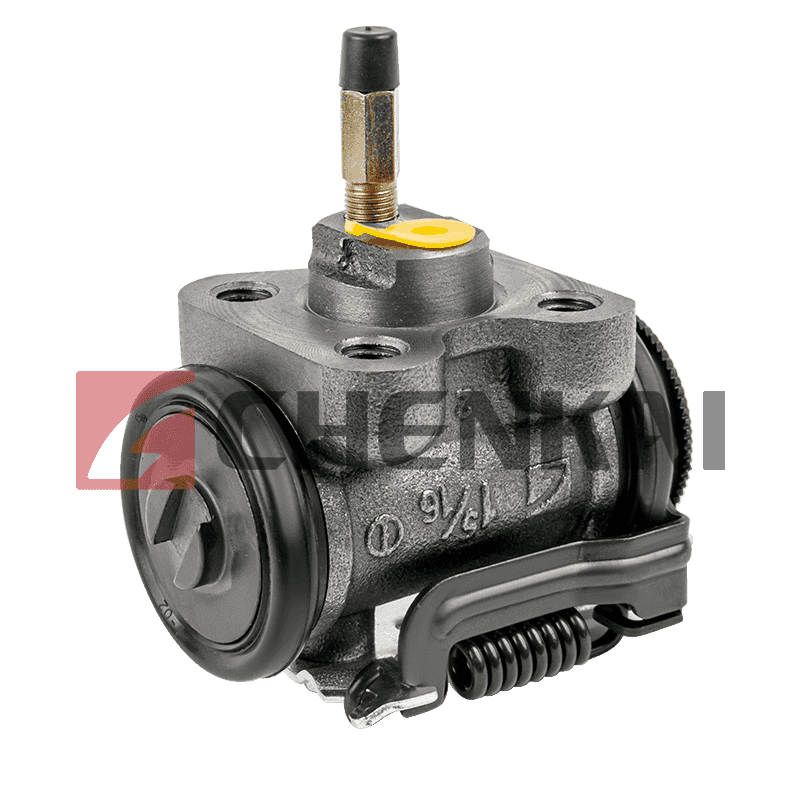

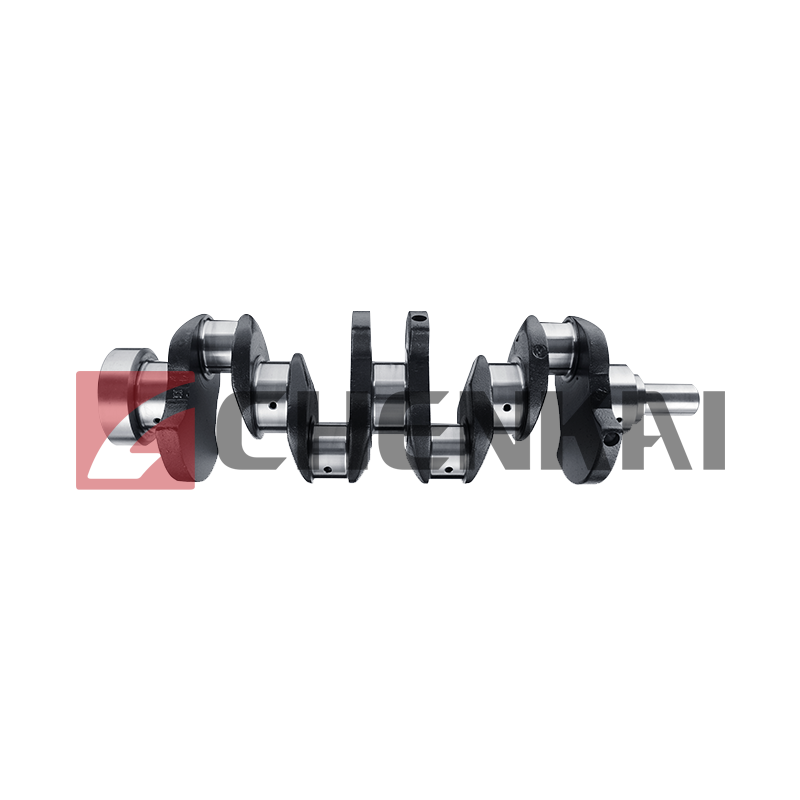

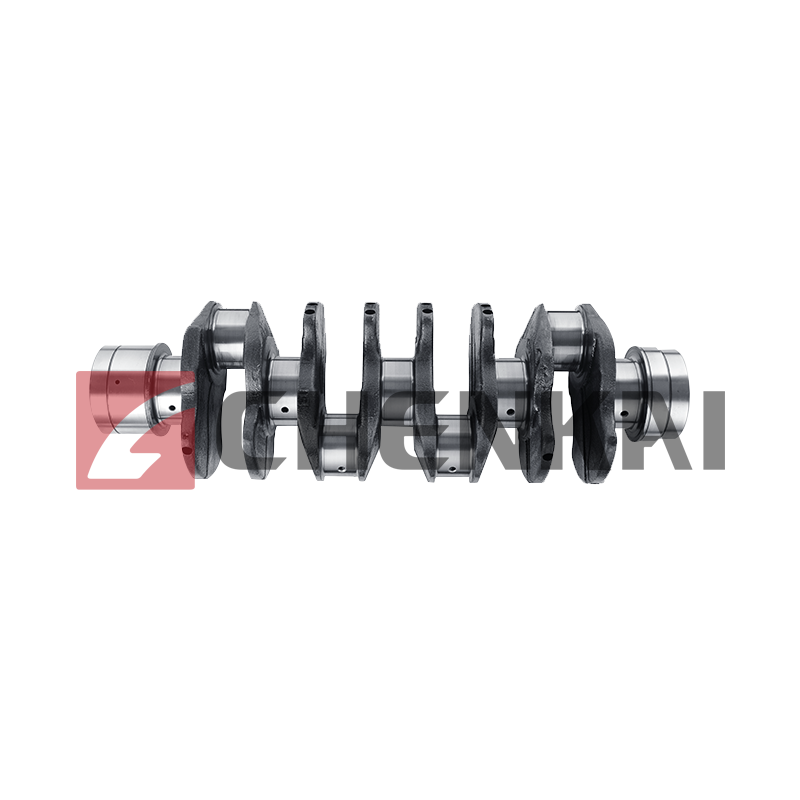

Related Products

Catalogue

Request more information

Contact Information

+ 86 139 5828 3988

+ 86 139 5828 3988 + 86 (0) 574 63574223

+ 86 (0) 574 63574223 info@chenkai.com

info@chenkai.com No.20, Zhendongzhi Road, Xinpu Industry District, Cixi, Zhejiang, China

No.20, Zhendongzhi Road, Xinpu Industry District, Cixi, Zhejiang, China

English

English русский

русский Español

Español